Accumulator Bladder Dealers in Chennai

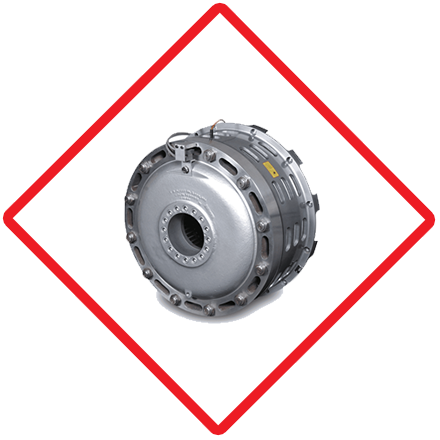

Accumulator Bladder Dealers in Chennai– Engineering Access is a top Accumulator bladder dealer in a hydraulic fluid-holding pressure vessel in Chennai.

Accumulator Bladder Dealers in Chennai – Engineering Access offers bladder accumulators that are designed for low-pressure fluid systems. This bladder accumulator is ideally suited for the Energy, Process & Marine Markets, and is available in volumes 0.5 to 575 liters, in carbon steel (20 to 80 bar), and in stainless steel (20 to 40 bar).

Additional this accumulator offers a reliable and efficient solution for water hammer arrestor, thermal expansion, energy storage, and pulsation dampening. Utilizing comprehensive tools and resources including an applications database, finite element analysis, reliability studies and simulation we have optimized the design and performance of the accumulator. A high volume solution has been specially developed for energy storage and thermal expansion. These bladder accumulators are suitable for use in more than 35 countries (all hydraulic accumulators for Chennai are CE marked) and they can meet an extensive range of international and industry approvals.

Give us a call! We’re here for you. +91 98841 25906

For any further information about equipments, email us at engineeringaccess2019@gmail.com

The standard series bladder accumulator in this series has a female threaded fluid port or optional flange fluid port with different flange design standards.

Product testing and continuous product development help to ensure our hydro-pneumatic accumulators operate at optimum efficiency and can perform in the most demanding environments. Parker accumulator accessories such as safety blocks, charging sets, brackets & clamps, adaptors, and flanges, lifting eyes, bladder kits, can aid the safe installation and operation of the accumulators in any hydraulic system.

Area Served

How It Works with Accumulator Bladder?

An accumulator bladder, also known as a hydraulic accumulator bladder, is a key component in hydraulic systems. It serves the purpose of storing hydraulic fluid under pressure and releasing it when needed to supplement the flow of hydraulic fluid in the system. This helps to maintain consistent pressure, absorb shocks, and compensate for variations in fluid volume.

Here’s how an accumulator bladder works:

Structure of the Accumulator

An accumulator typically consists of a metal shell or casing, a bladder or diaphragm, and a port for hydraulic fluid to enter and exit the accumulator. The bladder is the flexible component that separates the hydraulic fluid from gas (usually nitrogen) within the shell.

Charging the Accumulator

To start, the accumulator is charged with gas. Nitrogen gas is commonly used because it is stable and doesn’t react with hydraulic fluids. The gas is charged into the space between the metal shell and the bladder, creating a precharge pressure. This precharge pressure is typically set to a specific value, which depends on the requirements of the hydraulic system.

Hydraulic Fluid Storage

When the hydraulic system operates, it generates pressure and can sometimes experience pressure spikes or fluctuations. The accumulator bladder serves as a storage vessel for hydraulic fluid under pressure. As the hydraulic fluid enters the accumulator, it compresses the bladder and increases the gas pressure inside the accumulator. This stored energy can be released later to supplement the hydraulic system’s pressure.

Releasing Stored Energy

When the hydraulic system requires an additional surge of hydraulic fluid or experiences a sudden demand for high-pressure fluid, the accumulator bladder releases the stored energy. The pressurized gas forces the bladder to contract, pushing the stored hydraulic fluid out of the accumulator and into the hydraulic circuit. This helps to maintain consistent pressure and flow in the hydraulic system, even during peak demand or transient events.

Shock Absorption

Accumulators are also used to dampen and absorb shocks and vibrations within the hydraulic system. The flexibility of the bladder allows it to absorb sudden pressure changes and protect the system from damage or instability.

Maintaining Pressure

Over time, as the hydraulic fluid is released and the gas pressure decreases, the accumulator can be recharged with gas to restore its precharge pressure. This is typically done during regular maintenance intervals or when the precharge pressure falls below a certain threshold.

Accumulators are widely used in hydraulic systems for various applications, including heavy machinery, industrial equipment, and hydraulic power units. They help improve system performance, reduce energy consumption, and protect components from pressure fluctuations and shocks. The type of bladder and the size of the accumulator are selected based on the specific requirements of the hydraulic system.

For visit us google maps

Accumulator Bladder Dealers, best Accumulator Bladder Dealers in chennai